We strive for the best

equipment for the job

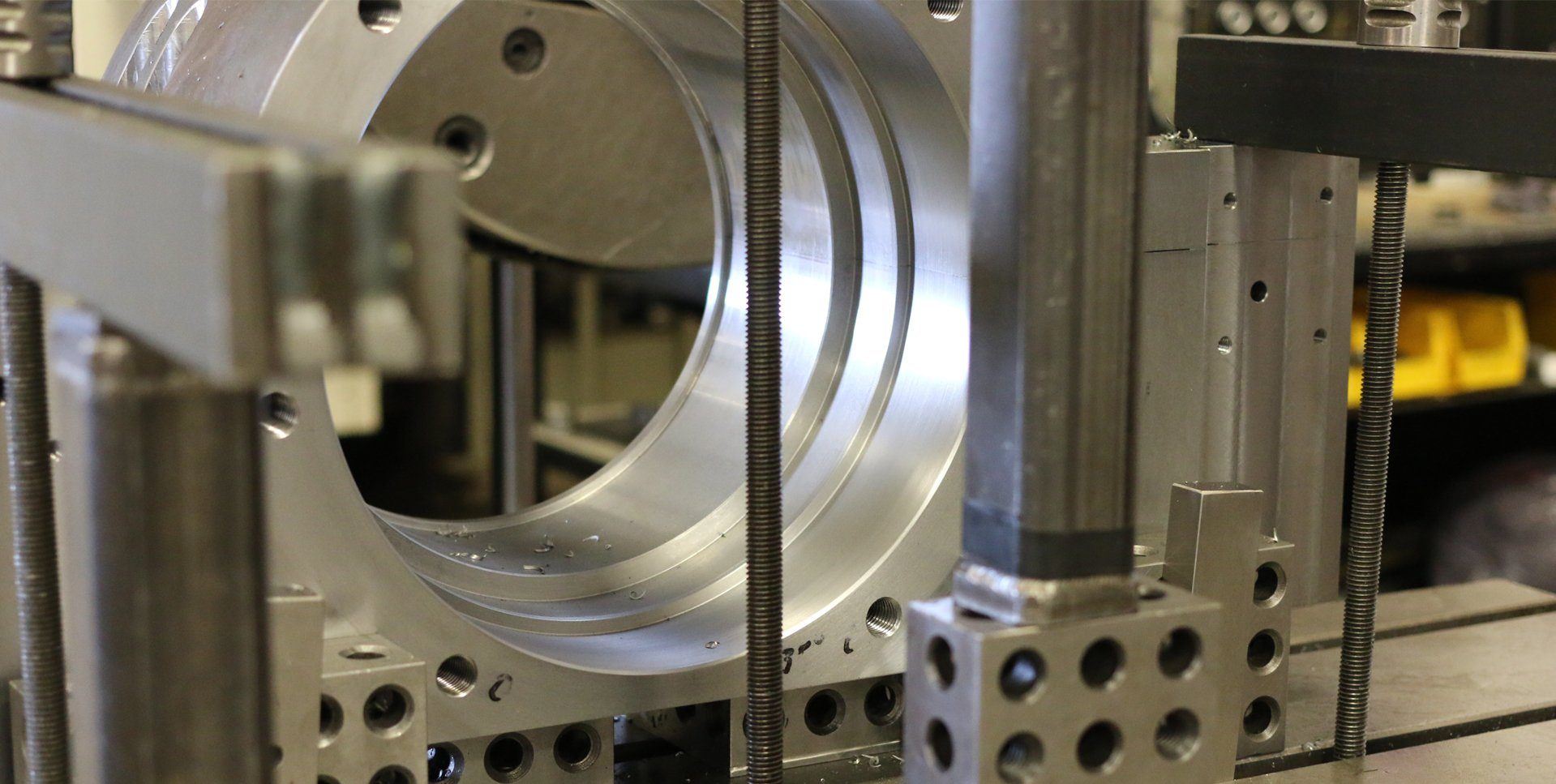

Continuous investment in the latest

machine technology insuring maximum

efficiency and consistent quality